From Coconut Husk to Finished Product: The Complete Coir Manufacturing Process

Ever look at a coconut husk and see a global export powerhouse? In the heart of Kerala, we do not see waste; we see the Golden Fiber. If you are a buyer or researcher, understanding the coir manufacturing process is the only way to ensure you are getting world-class durability and performance.

This guide explains the journey from raw material to finished product. It covers traditional retting methods and modern high-speed coconut fiber extraction. You will also learn how we maintain quality standards in fiber grading and industrial processing. This knowledge helps you make informed sourcing decisions. It is time to look past the husk and see the technical engineering behind the fiber.

An expert walkthrough of the coir manufacturing process, detailing extraction, retting, and the final grading of fibers for global exports like geotextiles and mats.

Phase 1: Raw Material Sourcing: Coconut Husk

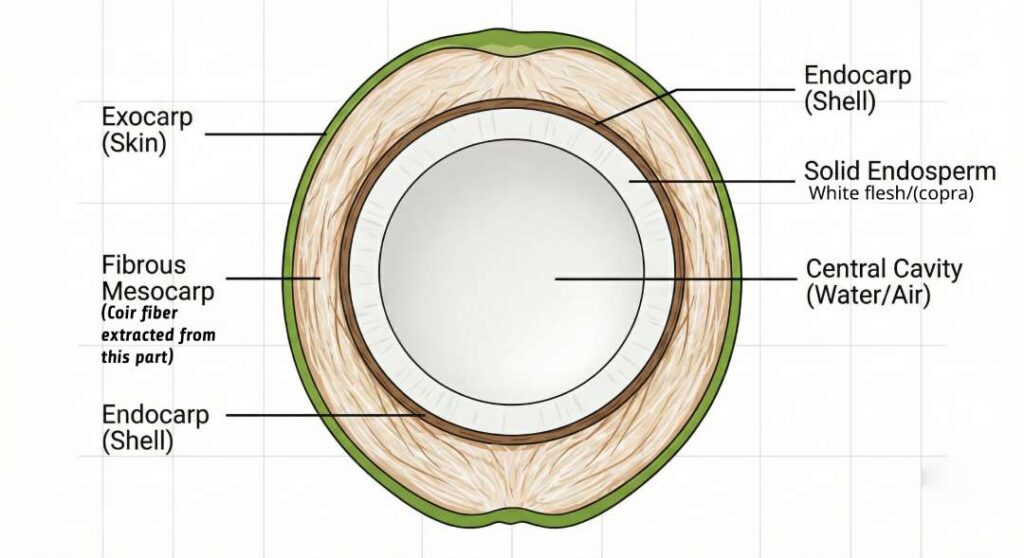

The coir manufacturing process begins at the raw material stage, where coconut husk selection directly determines fiber strength, length distribution, and processing efficiency. Producers source husks as a by-product of coconut processing for copra, oil, or food applications. They collect husks primarily from established coconut-growing regions. To maintain consistency, processors segregate husks at the source based on maturity, moisture content, and exposure to weathering. Poor handling or prolonged outdoor storage can initiate microbial degradation, which weakens fiber structure even before retting.

Additionally, commercial coir production utilizes two categories of husks.

- Green husks, obtained from immature coconuts, produce finer and more flexible fibers due to lower fiber wall thickness and higher elasticity. Manufacturers commonly use these fibers for yarn spinning, twines, and products that require pliability.

- Brown husks, sourced from fully matured coconuts, yield coarse fibers with higher lignin content and superior tensile strength. This makes them suitable for coir mats, geotextiles, erosion control products, and other load-bearing applications.

Furthermore, husk maturity is a critical control parameter in the coir manufacturing process. Properly matured husks produce longer staple fibers with consistent tensile performance and abrasion resistance. Under-mature husks result in short and weak fibers, while over-aged or sun-degraded husks reduce fiber cohesion during extraction. Controlling husk maturity at the sourcing stage reduces processing losses, stabilizes downstream yarn quality, and supports compliance with export performance requirements.

Phase 2: De-husking and Fiber Preparation

Subsequently, after sourcing, coconut husks undergo de-husking and preliminary preparation before fiber extraction. In industrial coir manufacturing, this stage focuses on removing the husk cleanly while preserving fiber integrity and minimizing mechanical damage that could affect downstream processing.

Processors carry out de-husking either manually or with mechanical de-husking machines, depending on production scale and labor availability. Many producing regions still rely on manual de-husking, which allows careful separation but limits throughput and increases labor intensity. Mechanical de-huskers deliver higher efficiency and uniform output, making them suitable for large-volume coir manufacturing operations. Operators must carefully control machine settings to prevent excessive crushing, which shortens fiber length and increases pith contamination.

After de-husking, processors subject the husks to initial preparation, including trimming, sorting, and temporary storage prior to retting or decortication. At this stage, operators remove foreign matter such as sand, stones, and residual shell fragments. Process teams also monitor moisture levels, since excessively dry husks resist retting, while overly wet husks promote premature microbial breakdown.

Proper fiber preparation at this phase ensures uniform retting behavior and consistent fiber release during extraction. Poorly prepared husks lead to uneven softening, higher fiber breakage, and increased processing losses. In a controlled coir manufacturing process, this stage acts as a stabilizing step that directly influences extraction efficiency, fiber length distribution, and overall product quality.

Phase 3: Retting and Fiber Extraction

Retting as a Critical Conditioning Stage

Processors use retting to condition coir fibers by breaking down natural binding materials that hold fibers to the husk matrix. The process softens pectins and hemicellulose while preserving fiber length and strength. Effective retting directly influences extraction yield, fiber tensile properties, and downstream processing efficiency.

Traditional Water Retting

In traditional coir manufacturing, producers soak husks in water for several weeks to months, depending on husk maturity and water conditions. Microbial activity gradually loosens the fiber bundles. When operators maintain optimal conditions, traditional retting produces long, high-quality fibers. Variations in water quality, temperature, or oxygen availability can cause uneven retting, fiber discoloration, and reduced strength.

Mechanical Extraction Using Decorticators

Modern production increasingly supplements or replaces retting with mechanical extraction using decorticator machines. Operators first condition husks to a controlled moisture level, then feed them into rotating beaters that physically separate fibers from the woody husk. Mechanical extraction accelerates processing and improves throughput but requires precise calibration. Excessive impact shortens fibers and generates fines, while insufficient action leaves fibers partially attached to the husk and increases pith contamination.

Initial Fiber and Pith Separation

After retting or decortication, operators perform initial separation to isolate long fibers from coir pith and short fiber fragments. Proper separation prevents contamination in subsequent stages. Inadequate separation increases cleaning requirements, reduces yarn uniformity, and can negatively impact the performance of finished products.

Phase 4: Cleaning, Drying, and Defibering

Following extraction, coir fibers require systematic cleaning and moisture stabilization before they can be graded or converted into value-added products. At this stage of the coir manufacturing process, the focus shifts from separation to refinement, ensuring the fiber meets mechanical, dimensional, and cleanliness requirements for downstream processing.

Extracted fibers typically contain residual pith particles, dust, and organic impurities. Cleaning is carried out through a combination of manual shaking, sieving, and mechanical beating, depending on production scale. Effective removal of pith at this stage is critical, as retained fines interfere with spinning efficiency and reduce the uniformity of yarn and woven products. Excessive mechanical cleaning, however, must be avoided to prevent fiber breakage and loss of usable length.

Coconut Fiber

Moreover, drying is then performed to bring the fiber to a controlled moisture content suitable for storage and further processing. Sun drying remains widely used due to its low energy input. But producers apply controlled drying systems where climatic conditions remain inconsistent. Uniform drying is essential for fiber stability. Fibers that retain excess moisture become susceptible to microbial growth. Over-drying, in contrast, increases brittleness and handling losses. Moisture stability at this stage directly influences fiber flexibility and tensile behavior during spinning.

Defibering is the final refinement step, where fibers are separated into distinct categories based on length, thickness, and stiffness. Bristle fibers consist of long, coarse strands used in mats, brushes, and geotextiles. Mattress fibers are shorter and more flexible, commonly used in cushioning and rope applications. Omat fibers, being the shortest fraction, are typically diverted to applications where bulk filling or blending is required. Accurate defibering ensures predictable performance in subsequent manufacturing stages and minimizes material wastage.

Phase 5: Grading and Sorting of Coir Fiber

After cleaning, drying, and defibering, manufacturers grade coir fiber to ensure consistent mechanical performance and suitability for specific applications. Within the coir manufacturing process, grading serves as a quality control mechanism that aligns inherent fiber characteristics with defined product specifications, thereby reducing variability in finished goods.

Manufacturers base grading primarily on fiber length, tensile strength, thickness, color, and cleanliness. They classify long fibers with uniform diameter and minimal pith content for high-strength applications such as coir mats, mattings, geotextiles, and erosion control products. Producers allocate medium-length fibers to yarn spinning and rope production, where flexibility and processability remain critical. Although short fibers do not meet structural performance requirements, manufacturers retain them for applications that prioritize bulk and cushioning over tensile strength.

Sorting is performed through a combination of manual inspection and mechanical separation. Manual grading allows visual assessment of color consistency and contamination, while mechanical systems improve throughput and reduce subjectivity. Consistent grading at this stage is essential for maintaining uniform yarn twist, predictable weaving behavior, and stable product dimensions.

Consequently, export-oriented coir manufacturing requires adherence to defined grading standards to meet buyer specifications and regulatory expectations. Fibers that fall outside acceptable tolerances are either reprocessed or diverted to alternate applications. Effective grading minimizes rejection rates, improves production planning, and ensures that each batch of fiber performs reliably in subsequent manufacturing stages.

Phase 6: Spinning and Yarn Manufacturing

Spinning converts graded coir fiber into a continuous form suitable for weaving, braiding, or further fabrication. Within the coir manufacturing process, yarn quality serves as an intermediate performance indicator, since variations introduced at this stage directly affect the strength, appearance, and dimensional stability of finished products.

Before spinning, processors condition the fibers to achieve uniform moisture and flexibility. This conditioning reduces breakage during twisting and supports consistent yarn formation. Manufacturers perform spinning using either traditional hand-operated wheels or automated spinning machines, depending on production scale and yarn specification. Hand spinning allows finer control over twist density and supports specialty or low-volume products, while automatic spinning machines deliver higher output and repeatable quality for industrial applications.

During spinning, operators twist fibers to a defined turns-per-meter ratio to achieve the required balance between tensile strength and flexibility. Insufficient twist produces weak yarn with poor cohesion, while excessive twist increases stiffness and reduces weaving efficiency. Operators continuously monitor yarn diameter, twist consistency, and surface cleanliness, as deviations at this stage can introduce defects during weaving or braiding.

After spinning, operators wind the finished yarn into spools or balls and inspect it for uniformity before releasing it for downstream processing. Consistent yarn manufacturing stabilizes subsequent operations such as mat weaving, rope twisting, and geotextile production. Proper process control at this stage preserves the mechanical properties developed in earlier phases through to the final product.

Phase 7: Manufacturing Finished Coir Products

Manufacturers convert coir yarn and fiber into finished products at the stage where functional performance and application-specific requirements fully materialize. In the coir manufacturing process, this phase integrates material properties developed in earlier stages. It combines these properties with mechanical forming, weaving, or bonding techniques. These methods produce end-use products with defined dimensions and performance characteristics.

Manufacturers produce Coir mats and mattings through weaving or tufting processes depending on design and usage requirements. Woven mats utilize coir yarn interlaced on looms to create dense, abrasion-resistant surfaces suitable for residential and commercial flooring. Tufted mats involve inserting coir yarn into a backing material, allowing greater flexibility in pattern and thickness control. Consistency in yarn tension and weave density is essential to ensure uniform thickness and wear resistance across the product.

In addition, manufacturers produce coir geotextiles in both woven and non-woven forms for erosion control, slope stabilization, and soil reinforcement applications. Woven geotextiles use controlled yarn spacing and tensile alignment to meet specific strength and elongation requirements, while producers create non-woven variants through needle-punching techniques that mechanically bond fibers into a stable matrix. Engineers define product specifications based on application conditions such as load, flow velocity, and expected service life.

Manufacturers form coir ropes and twines by twisting multiple yarn strands into structured assemblies that withstand tensile and abrasive forces. Producers adjust twist direction, strand count, and diameter according to marine, agricultural, or industrial use. For specialty products such as coir logs and nets, manufacturers assemble graded fibers or yarns with selected binding techniques to achieve controlled density and predictable degradation rates.

Phase 8: Quality Control and Export Packaging

Quality control operates throughout the coir manufacturing process, but the final inspection stage functions as the last verification point before dispatch approval. At this stage, inspectors evaluate finished coir products to confirm compliance with dimensional, mechanical, and moisture-related requirements specified by buyers or applicable regulatory standards.

Inspection parameters vary by product type but commonly include checks for thickness, weight per unit area, dimensional tolerance, and visual uniformity. For load-bearing or technical products such as coir geotextiles and ropes, inspectors assess tensile strength and elongation behavior to verify consistent performance under applied stress. Inspectors also monitor moisture content, as excessive residual moisture promotes microbial growth during transit and storage, while overly dry products become brittle and prone to damage.

After approval, operators prepare products for export packaging. They typically roll or fold mats, mattings, and geotextiles and compress them to optimize container utilization without compromising structural integrity. Operators bundle and secure ropes, twines, and logs to maintain shape during handling. They select packaging materials to protect products against moisture ingress and mechanical damage during transportation.

Operators perform baling and compression under controlled conditions to achieve uniform package dimensions and weight. They label each shipment for traceability, linking batches to production records. Effective quality control and packaging at this stage minimize transit-related damage, reduce rejection risk at destination ports, and ensure that products reach end users in a condition consistent with specified performance and application requirements.

The Sustainability Advantage

The coir manufacturing process demonstrates how an agricultural by-product can be transformed into a technically reliable and environmentally responsible material. By converting coconut husk into functional fibers and finished products, the industry delivers solutions that combine mechanical performance with biodegradability and low environmental impact.

Unlike synthetic alternatives, coir products are derived from a renewable resource and return safely to the environment at the end of their service life. This makes coir particularly suitable for applications such as erosion control, landscaping, and natural flooring, where temporary performance followed by biodegradation is often desirable. The durability of coir during use, followed by controlled degradation, is a direct outcome of the material characteristics developed throughout the manufacturing stages.

Understanding the full coir manufacturing process allows buyers and specifiers to select the appropriate fiber grades and products for their intended applications. When sourcing coir products, process transparency and material control are key indicators of consistent quality and long-term performance.

Meet the Expert

This technical guide was prepared by an Export Manager based in Alleppey, Kerala. With professional expertise in managing international client accounts and overseeing export logistics for Jayasree Coir Mills, providing first-hand insights into the manufacturing and global distribution of sustainable coir products.